Ghana chin chin is a fried dough block, with square, triangle, diamond, round, strip shape and so on. How to make ghana chin chin, we will teach you here.

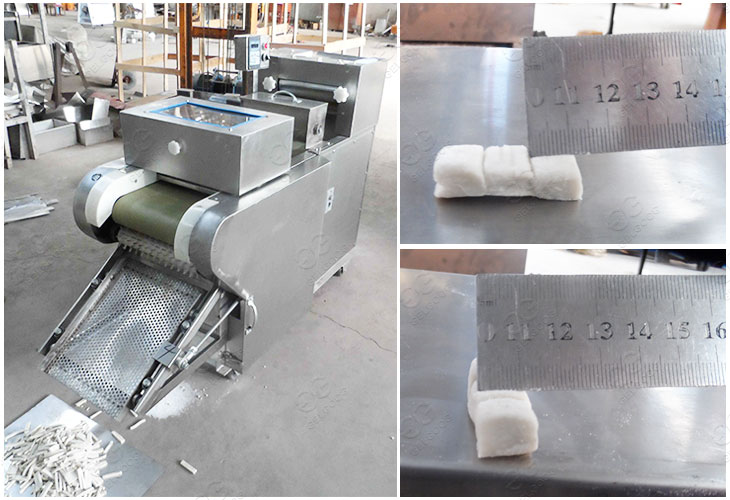

As a chin chin manufacturer, the efficiency of hand-made can not meet people’s needs, we use chin chin cutting machine instead of hand-made. In the manufacturing process, only need to put the flattened dough sheet into the feed port to make it into the shape and size you want.

Here is the working principle of ghana chin chin cutting machine:

- Put a certain amount of dough on the upper feeding panel, start the machine, and transfer the fabric to the roll room.

- The fabric is automatically fed and pressed by the conveyor belt and rollers to achieve the ideal processing thickness.

- The roller gap can be adjusted steplessly through the adjustment wheel, and the user can master it according to the pasta process.

- The rolled dough sheet is fed into the dough point forming mechanism through the conveyor belt, and cut and processed. It can cut a variety of patterns such as sheet, block, wire, dice, diamond, and curve.

What is the main function of ghana chips cutting machine?

- The food contact part is made of 304 stainless steel, the machine is shiny and beautiful.

- Each machine is equipped with 5 knives, which can be cut into diamond, square, triangle and so on.

- The cutting range is: material length within 280mm, width 0-40mm, conventional thickness 3-15mm.

- With intelligent control system, it can realize conveyor belt and cutting speed adjustment.

- It is an important equipment in the production line. Dough mixer machine–dough pressing machine–cutting machine–frying machine–packaging machine.

The chin chin cutting machine is mainly composed of frame, transmission part, pressing part, cutting part and conveying part. It is the best equipment for making ghana chin chin.